Nitinol

Nitinol combines two closely related unique characteristics: shape memory and superelasticity.

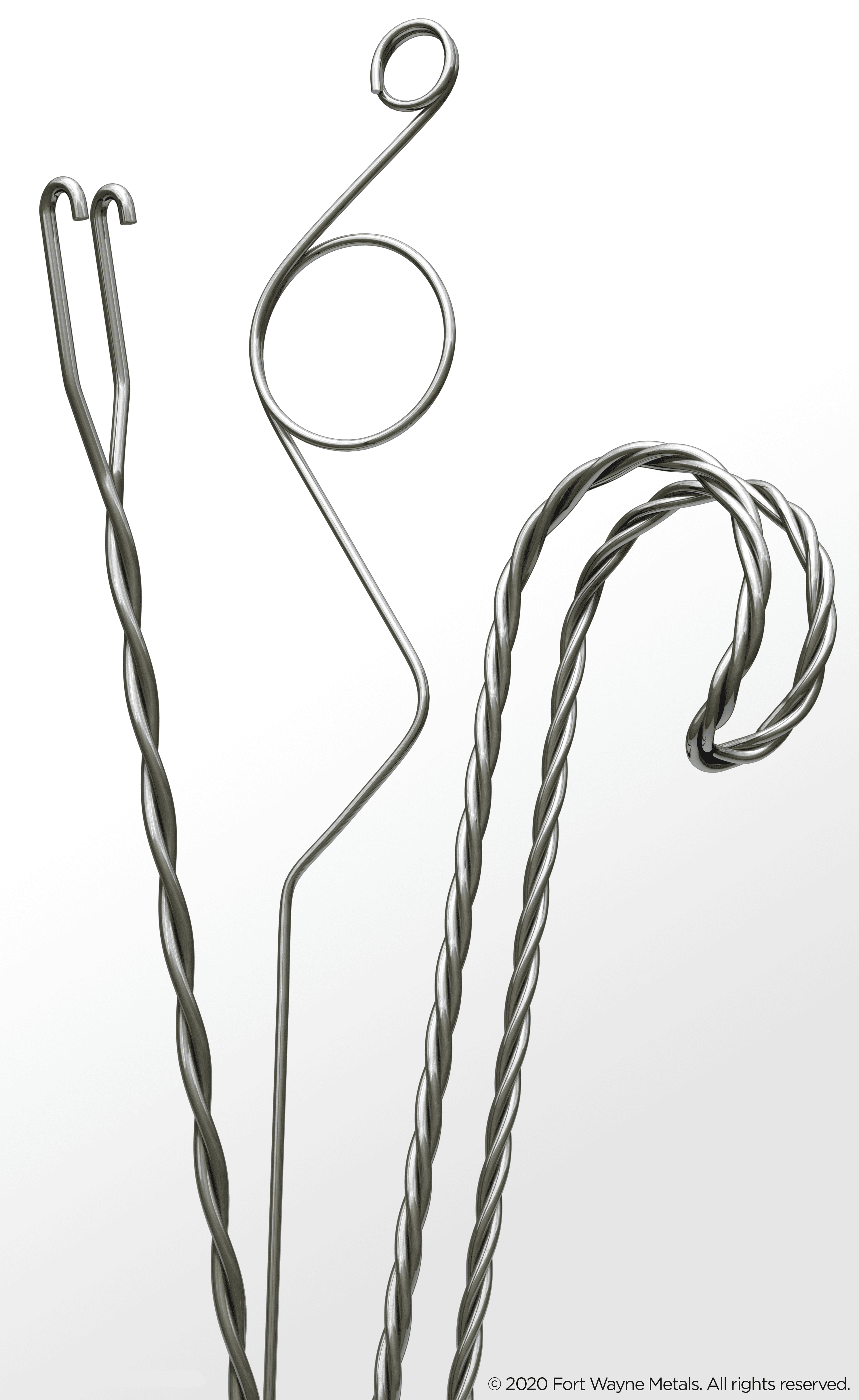

Shape memory gives Nitinol the ability to be deformed at one temperature, and then return to its original shape when being heated to its transformation temperature. This effect is caused by the material changing from its low temperature monoclinic martensitic structure to the high temperature cubic austenitic structure. Transformation temperatures in our finished Nitinol wire range from -15°C to +22°C, depending on the grade of Nitinol used. Shape memory Nitinol wire can be used to develop implants that may be delivered into the body in a compact shape and then activated into their functional form once they have been deployed.

Superelasticity occurs at temperatures just above the transformation temperature and allows the material to recover from up to 8% strain with a permanent set of 0.5% or less.

Nitinol Wires

Nitinol Wire:

Fort Wayne Metals manufactures wire products from various grades of Nickel-Titanium or Nitinol commonly used in medical applications (Nitinol #1, Nitinol #2, Nitinol #4 and Nitinol #8) as well as Nitinol #5, Nitinol #6, and Nitinol #9 for other various applications. All Nitinol grades are available in either the cold worked condition ready for heat treatment or as straightened super-elastic wire.

Each medical grade of Nitinol material is comprised of near equal atomic weight percentage of Nickel and Titanium. With the exception of grades 2 and 3, all Nitinol grades meet the chemistry requirements set forth by ASTM F2063 for use in surgical implants – in fact, they are of higher purity than required by ASTM.

Nitinol Wire Applications:

Our Nitinol wire is used for many different medical and industrial applications. The table below gives some typical engineering applications for each of our standard Nitinol medical grades:

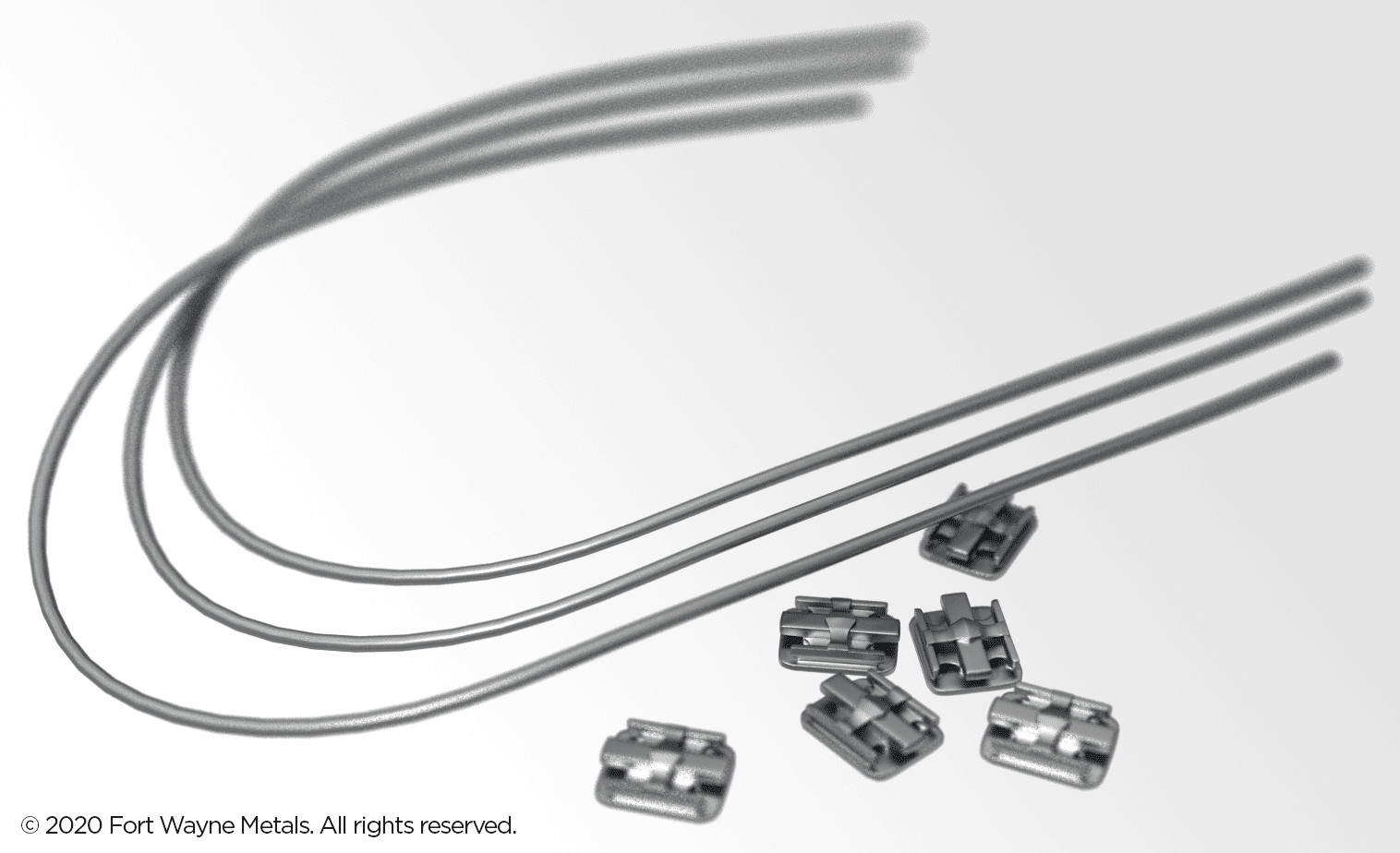

Nitinol #1 Guidewires, stents, stylets, forming mandrels, stone retrieval baskets, orthodontic files, etc.

Nitinol #2* Ideal for applications that require a high loading and unloading plateau stress at room temperature. Chromium doped for decreased transformation temperature and increased tensile strength.

Nitinol #3** Applications requiring increased stiffness. Cobalt doped for decreased transformation temperature and increased tensile strength.

Nitinol #4 Provides the best cycling performances at body temperature (37°C), for example in orthodontic arch wires.

Nitinol #5 A common application for this alloy is high temperature actuators.

Nitinol #6 A common application for this alloy is high temperature actuators.

Nitinol #8 Ideal for applications that require a phase transformation at body temperature (37°C).

Nitinol #9 For use in very cold temperature environment applications.

* Typical chemical composition: ASTM F2063 Exc. Cr 0.2% to 0.3%

** Typical chemical composition: ASTM F2063 Exc. Co 1% to 2%

Request a Quote

More information, please feel out the form below