WaterJet Micro Cutting

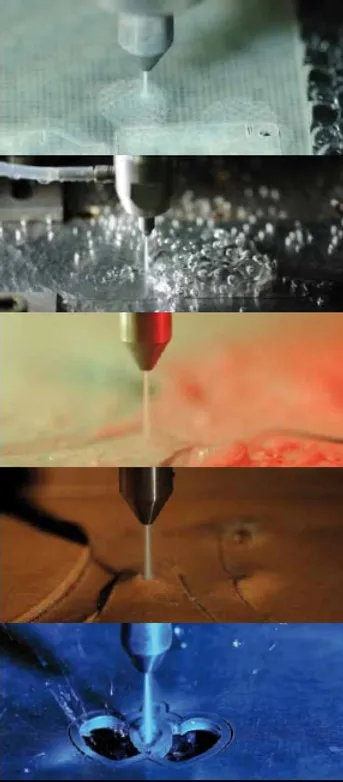

Cutting a wide range of materials, including heat

sensitive ones, with a cutting accuracy of +/-0.01 mm

and a positioning accuracy of +/-0.0025 mm, the

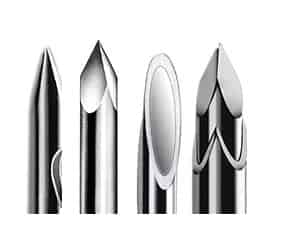

e-dro micro waterjet cutting process occurs by mixing

very fine abrasives and accelerated water at around

800 m/s – 3 times the speed of sound.

Low cutting forces with no thermal impact, make it

possible to cut the most intricate contours, assuring

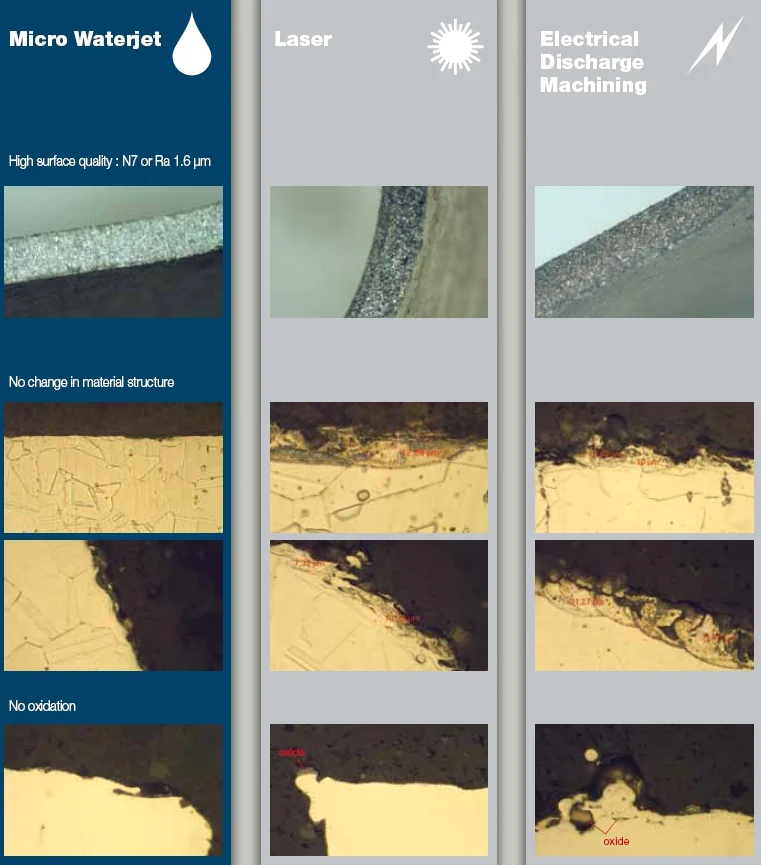

burrs on the cutting edge are minimal and a high

surface quality equivalent to N7 or Ra 1.6 μm.

Thanks to a waterjet whose diameter is smaller than

0.30 mm, we can provide high cutting speeds and

high quality for sharp and narrow outlines. More

competitive than classic waterjet cutting, EDM or laser;

the micro waterjet cuts plastics, ceramics and

conductive materials with ease.

- High surface quality : N7 or Ra 1.6 μm

- No change in material structure

- No oxidation

- No thermal impact

- No tooling cost

- Minor burrs on the cutting edge

- Optimal use of material

- Little to no rework

- Fast and competitive prototypes

- Low cutting forces

- Positioning accuracy (ISO 230-2) : 2.5 μm

- Cutting repeatability (ISO 230-2) : 2.5 μm

- Cutting accuracy (depending on material

- and thickness) : +/- 0.01 mm

- Maximum piece size : 990 mm x 590 mm

Request a Quote

More information, please feel out the form below